We help our customers from start to finish. This means we are happy to be involved from the very beginning of a potential project, all the way through to the installation of the piping system. To make this happen, we have all the disciplines and expertise in-house. It starts with the design, continues with the production of the product, and ends with the installation of the piping.

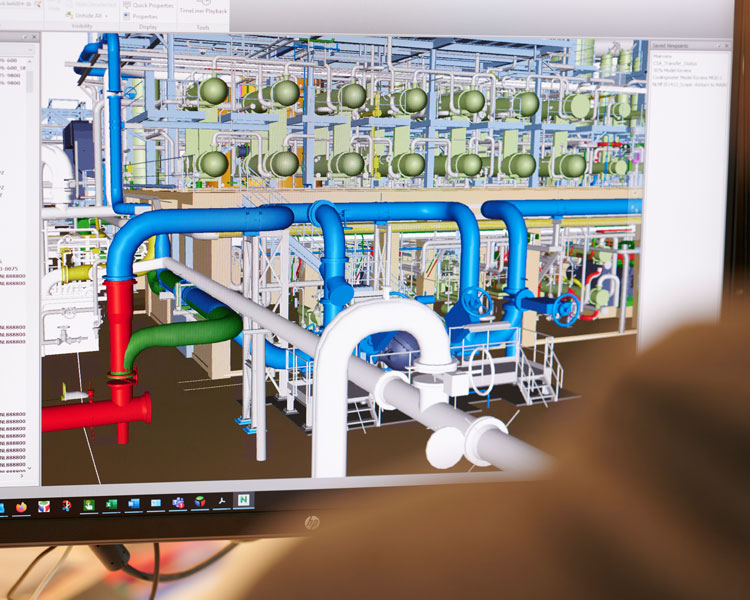

Versteden’s engineers are eager to be involved from the very start. With our specialized knowledge, extensive experience, and strong commitment, we provide both requested and unsolicited advice for the right technical and sustainable solution. Every project, large or small, begins with a thorough project analysis and design. Our engineers collaborate to find the best solutions and minimize risks.

Our added value during the design process:

At our production facility, we have interconnected production departments. We press flanges, wind pipes, fittings, bends, and reducers. We have a welding workshop, and in the prefab department, we assemble the pipes as much as possible for efficient installation.

Our added value during the production process:

Before we can install a piping system, we ensure that it leaves our production facility as fully prepared as possible. This way, our technicians can efficiently and according to schedule install the piping system at the customer's site.

Added value of the installation team: